Struthers Watchmakers, U.K. visit Dec 2024

I made the trek over to Leek, Staffordshire from North Wales where I was staying with family over the Christmas Holidays. I had to drop off family members at Manchester airport at 6.30am, so headed down towards Leek in the dark of winter. I had set up our meeting prior with Dr. Rebecca & Craig Struthers and they kindly agreed to meet me quite early on the Sunday morning after Christmas Day. No coffee shops were open in Leek until 8am, however I got to see around the center of this lovely old town, a former textile mill town where the Struthers moved their workshop to a few years ago.

The Town square in Leek

The cobblestone center of town.

We had arranged to meet around 8am, so I headed over there as soon as I could grab a coffee. A short drive to the old mill building, where Craig & Rebecca have their atelier.

The non-descript doorway in the old Mill building, the “CRS” logo is all that announces them.

I was greeted by Craig with a smile and we headed upstairs. The new space is quite a bit smaller than their old space I visited back in 2019, in the Jewellery Quarter of Birmingham. They have their trusty old but restored “named” machines along one wall and their watchmaking benches facing each other as before. Familiar tools of the trade!

I was shown, but not allowed to take photos, a Project 248 model in red gold with a lovely black enamel dial that was in the workshop for some tweeking. As with many new watch models that are eagerly wanted on the wrists of those who order them from artisanal independent watchmakers, there is often a teething period where the actual live usage on the wrist of said wristwatch, reveals small issues that weren’t anticipated in the original design or protyping stage. There is nothing like real daily wear and tear on a wristwatch, to properly field test a watch design. Rare does the small artisanal independent have the time and ability to do this extensively enough to cover all types of events that can occur with wearing a watch. Luckily, this owner is understanding and knows that he/she is contributing massively to the Struthers’ ability to improve upon their work. Future collectors will benefit and in the spirit of being a patron, as the early adopters so often are, those collectors typically will readily and happily help out the watchmaker. My suspicion here may be off base, but I suspect I’m pretty close to the reality, so my hat’s off to the collector for supporting Rebecca & Craig in the early days.

Dr. Rebecca Struthers & Craig Struthers.

One thing to note that has changed since my prior visit, is that they have changed their business model now to reflect where they want to focus their precious time. They are only producing Project 248 watches from now on. No other models will be available, nor any outside repair or restoration work will be entertained by the Struthers anymore. My belief is that with this strict focus on one watch, they will be able to dedicate their resources more efficiently and build more watches for collectors, which is good news for those eagerly waiting a Struthers Project 248 watch!

I found this early production Project 248 watch to be quite charming, elegant and very well made for a first effort. Not an easy task to accomplish, it features a very slow beat balance wheel that is visible on the back of the caliber. The beautifully hand engraved movement in the classically English floral style is a joy to see. German silver has that lovely warm feel to it and the slow oscillating balance wheel, a real treat. They use several master craftspeople in different fields as in the old days. A superb hand engraver, Florian Guellert, does exquisite work. The enamel dial is created up in Glasgow, by AnOrdain, the enamel dial specialists in the UK.

Some of the heavier equipment in the outer office space.

A goldsmiths bench, that is well used. Rebecca initially trained as a goldsmith prior to moving over to watchmaking.

The Struthers explained what they are up to next with their inhouse watch Project 248, exciting things to come and those supporters will be well rewarded. I was told in confidence a couple of upcoming aspects of future watches, and these will remain untold until such time that these two people decide to reveal to the world, what they are up to. I realize that so much of their world is in flux and the mistake of revealing a feature or design too early can have negative consequences down the road.

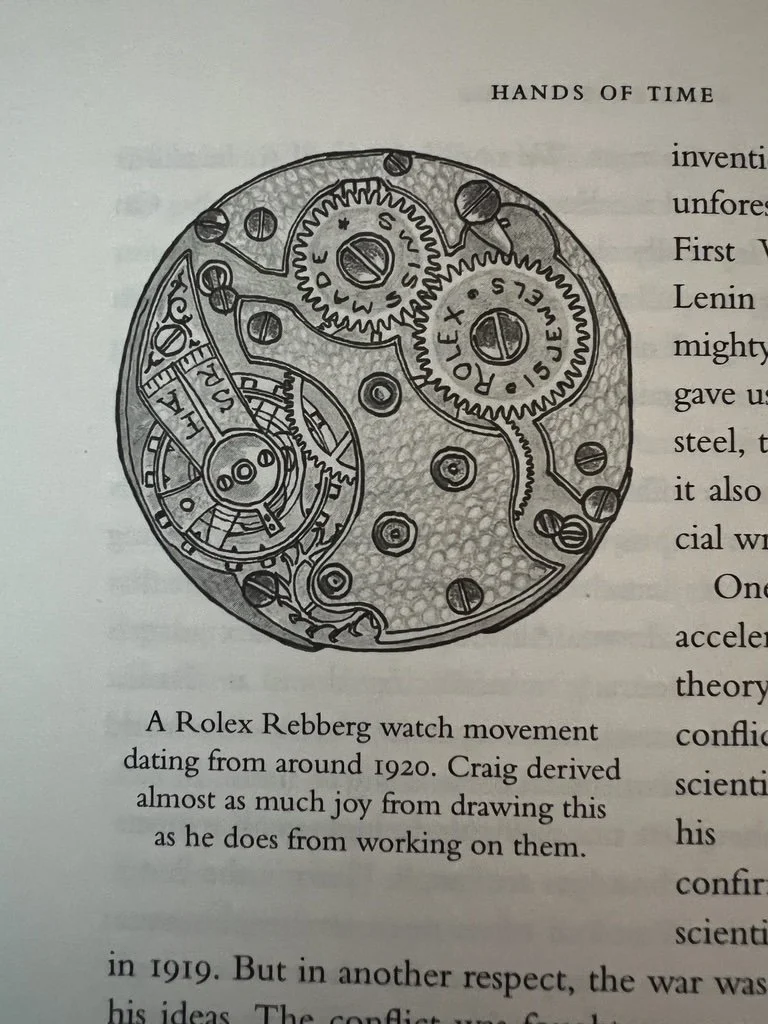

I strongly recommend Rebecca’s book, Hands of Time, to anyone remotely interested in Horology and the history of watchmaking. As the sole PhD in Horology, Rebecca’s brilliant mind and experience is laid bare for the reader. Her documentation and way of writing is easy reading even for the non technical watch buff. I thoroughly enjoyed this book, and it definitely gives one a better of sense of the watchmaker that Rebecca has become.

The English and USA versions. Had to have both!

I am always in awe of artisanal independent watchmakers that have dedicated their lives to creating mechanical wristwatches to the best of their ability and who focus on fine hand work to reveal their understanding of the classical ways of finishing that improves and longevity, look and feel of a watch. Rebecca and Craig certainly embody this philosophy.

One of Craig’s many illustrations found within the brilliant book.

Thank you Rebecca and Craig for another lovely visit.

Cheers,

Tim