Dan Spitz Visit July 5-6th, 2024, Delray Beach, FL.

I arrived from Boston, into a hot and steamy Florida evening on July 4th, 2024, Independence Day, an apt day for this story. Independence is what Dan Spitz is all about. In his previous career in the music industry, Dan was known for pursuing his independent creative streak as the lead guitarist for the group Anthrax. While I’m no expert on that particular period of his life, what I can tell you is that he has honed his skills over many years in a variety of fields. His watchmaking came naturally, as his grandfather owned a watch and jewelry store in upstate NY, and used to share with his young grandson fabulous works of “top of the range” horology. From an early age Dan was handling vintage watches made by Patek Philippe, Vacheron Constantin and Audemars Piguet. The horology seeds were sown at a young age due to this exposure.

The morning of the 4th July, Boston Harbor and the USS Constitution taking a leisurely tour before going back to her berth.

When Dan transitioned out of the music business, his natural love of watches and horology was the obvious path. He was accepted in the Wostep school in Neuchatel, Switzerland under the tutelage of the brilliant Antoine Simonin. Here he was able to glean much from the master, Antoine.

Fast forward to 2020, the Pandemic was upon us and yours truly was sitting at home spending hours online researching and learning more about my chosen field. Given the down time, this allowed me to find Daniel A. Spitz Watchmaker, based in the USA and do some research into the new watch that he was developing. His website back then featured some images of renderings of the caliber, and his use of as then, an un-announced escapement, the Libre Excentrique. It was co-developed by his dear friends and colleagues, the brilliant Luc Monnet at Arts Mechaniques in France and the talented Cyril Brivet-Naudot, another independent watchmaker. This Detent Chronometer single impulse escapement is extremely rare and difficult to execute even with todays modern machines that aid in the precision manufacturing. Intrigued by what I saw, I reached out to Dan online to see if we could connect. He replied that he’d be happy to speak on the phone. Our initial phone call lasted about an hour and I remember exactly where I was. He was gracious and forthcoming about what he was doing and why. I offered my services and willingness to help find potential clients for what I thought was a remarkable effort creating such a watch in the USA. We agreed to continue this conversation and from there over a few months I learned what I needed to about the mechanism and how he was going to implement it in his wholly conceived and designed watch. Using Titanium for the escapement parts, traditional German Silver for the two mainplates and steel for the flat work, bridges and cocks, he was going down the path of Independence from the usual suspects in Switzerland. He was in the process back then of programming his own CNC machine, that was to aid in precision repetition of these important parts. This self-reliance was a strong motivator for Dan. It struck a cord with me, as I had seen this over and over again with other independent watchmakers I have worked with over the years.

Since we had first spoke, I knew I wanted to visit Dan and see for myself his workshop and gain that ever precious insight into who Dan Spitz is as a watchmaker. Visiting a workshop/atelier of a watchmaker will always give one more reality and a much greater understanding of what they are up to. One also gets to meet the watchmaker and have that one on one interaction that you cannot duplicate over ZOOM or FaceTime!

His recent move to Florida, specifically Delray Beach, meant he was even farther away from California. However, the stars aligned and fittingly on Independence Day 2024 we finally met in person. He couldn’t have been more pleasant and as we shared our first dinner together, I felt happy that my initial sense of the man was correct.

The next morning waiting for Dan to open the locked door!

The anticipation was palpable, this is what I love to do!

That following day we met up at his atelier for a two hour session of watchmaking tools, techniques, machines used, multiple parts made in his workshop in Titanium and finally the prototype caliber. As I saw it, the prototype wasn’t complete and running, but enough was visible to recognize that this will be a unique, fascinating and highly prized American made caliber of historical significance. The huge balance wheel sits atop the movement, with the libre excentrique single impulse escapement below and visible. As a slow beat caliber, the owner will find this mesmerizing I’m sure.

What follows, are many “tools of the trade” as the old saying goes. I find them fascinating and each serves a very important role in the making of a watch. All these machines, much of them well over fifty years old, have all been carefully restored by Dan.

The table where his three watchmaking lathes are set up, the Schaublin 70, a Boley and also a Leinen. Head stock wooden box with all the necessary parts, that for the Boley and Leinen are interchangeable, sits at the back of this table,

The well used Boley lathe

The Leinen lathe

Head stock etc. for the Boley and Leinen!

We then moved to the testing bench, with a few familiar and not so familiar tools. An Antoine Simonin inspired machine that removes broken balance staffs without damaging the balance wheel center opening.

The tool that Antoine Simonin highly recommends for balance staff repairs!

Next was a Hamilton precision drill press, an early American made machine that allows for very precise “controlled by touch” drilling operations.

USA made Hamilton precision drilling machine

Here are some test prototype mainplates in brass.

Next is the familiar Perlage machine and one of Dan’s milling machines, the Aciera from Le Locle, Switzerland, that he has set up for his preferred style of Geneva stripes that are wide and similar to our old friend M. Dufour.

Perlage or spotting occurs here.

Dan’s Aciera set up for the Geneva stripes, with it’s variable-frequency-drive (VFD) digital controller on the front.

Here’s a test piece to show the wide stripping he prefers. A wooden spinning “head” is used that with the VFD, it’s RPM is controlled very precisely.

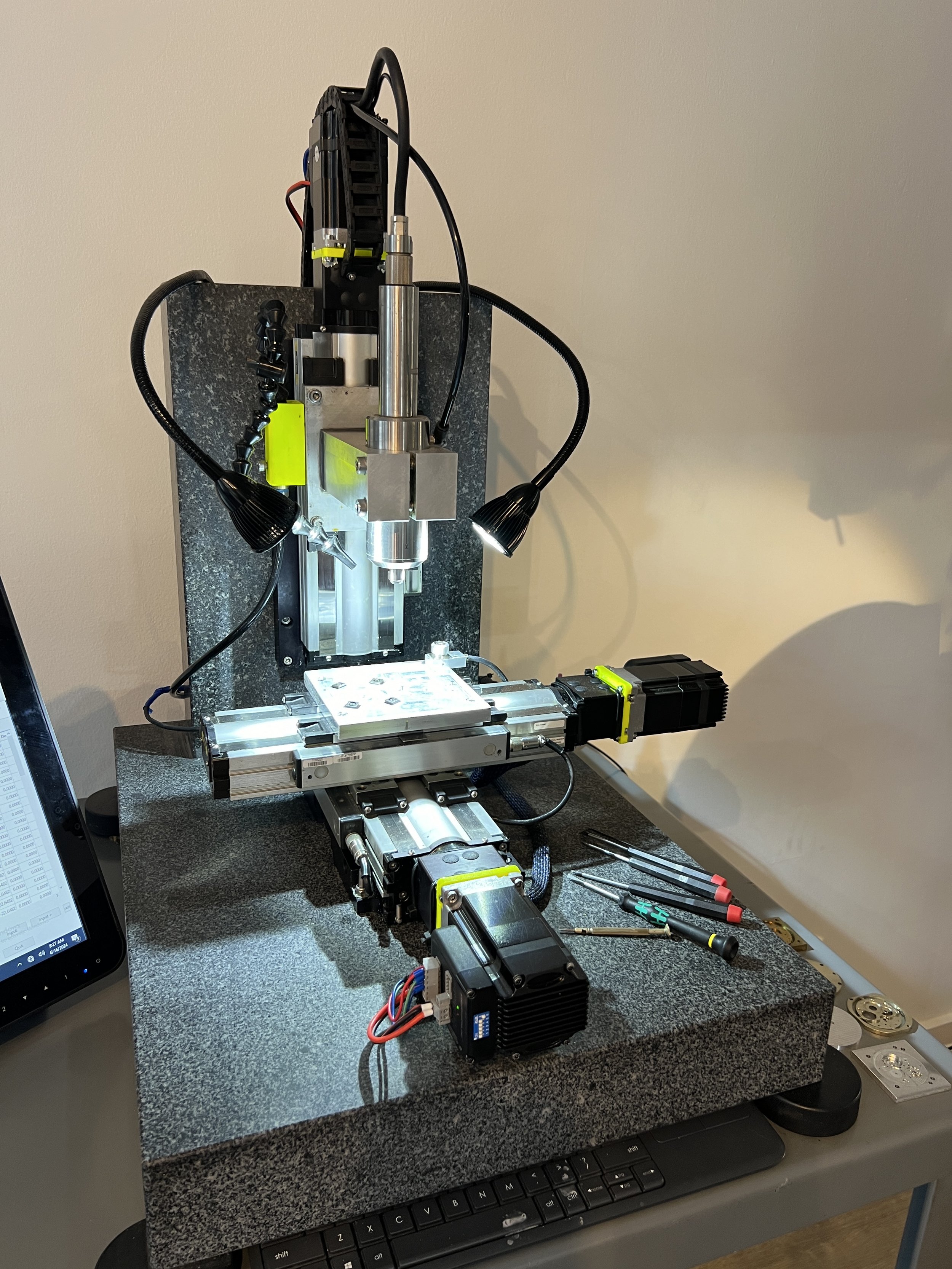

Dan’s CNC milling machine, built “in-house”

The self built and programmed CNC machine for prototyping parts in the required precision of down to a micron. This is what is needed in order to build watches that work and will work for years to come. In his past career, he built amps and other tools for his music to sound exactly as he wanted, shows me a clear aptitude for electronics, technology and mechanics. This is hugely helpful if one wants to train themselves on how to design, build & program a CNC machine!

The ability now to buy very high speed spindles from Japan, up to 30,000RPM that use air to drive them, allows for the required precision, together with the tungsten carbide and diamond impregnated drill bits.

Solid marble base and back for rigidity and mass to remain still during it’s use.

Another Aciera mill.

Multi axis milling machines set up with again the precise electronic measurement to a 1/100th mm

The Agathon, for producing precision specialist tools that are required in watchmaking. These machines are inside most self contained watchmaking workshops.

A very important tool and Dan swears by it to aid in his process of making watches.

Dan’s optical comparator by Nikon. This is used to check the shape and details at high magnification of parts, with the required design that is projected onto the big round screen.

Now we head into the back room, for more machines…

The Eddie Van Halen guitar paint style inspired tool! The heat bluing station is next to it on the left.

A lapping tool, for case work.

This is where the “dirty work” machines for polishing, lapping for case repairs, and his trusty 3D printer reside. Since seeing Marco Lang’s use of his 3D printer for prototyping ideas, tools and parts for the machines, the 3D printer gets used most days.

3D printer with a couple of old manual espresso machines to the left.

Then it was onto the main event, Dan’s bench, where his prototype caliber was sitting under a glass dome. The massive 18.4mm balance wheel made from a proprietary metal, floats above the caliber. This was not running yet, he has just completed his set up of this workshop since moving from Texas two months ago. He has trays of parts made and ready to go. The Titanium escapement parts were revealed and I had a chance to handle them and examine them under my 10x loupe. The titanium spring that he uses on the detent arm, is insanely thin, made in his atelier. Thinner than a human hair by a factor of 4! The Titanium chronometer escape wheel with it’s specially shaped teeth is also made in Dan’s atelier. This is impressive and not typically found here in the USA.

The work is progressing well and the delivery of his Titanium cases is the main hold up right now. They are coming from a US supplier who is pulled in many directions, much of which is his main job as a precision medical instruments supplier in Titanium parts and also as a specialist supplier of Titanium bicycle parts. With Dan’s limited quantities required, it is difficult to get one’s order prioritized, this I’m sure one can well imagine. Such is the life of an Independent Watchmaker!

Dan explaining what he is up to!

A close up of the non working prototype, with unfinished parts. He set this up for me to get an idea of what it will be like in due course. The “floating balance wheel” is a amazing and in the production piece it will be suspended on a black polished steel cock instead of the bridge shown here!

His business of watch repairs/restoration of rare high end pieces where his skill set and manufacturing ability will come into play, is being set up too. This after all has been a big part of his horology life since he began. This really important practical experience is so important for an independent watchmaker to have under their belt, as it allows for them to truly understand and appreciate what works over a long period of use and possibly more importantly, what doesn’t! Being able to handle, take apart and restore the great pieces from 100 years ago, gives a watchmaker, unavailable in watchmaking school, knowledge of materials and design that either stands the test of time or doesn’t.

Let me just say, I was enthralled and totally absorbed!

The Ti chronometer escape wheel on the left, the Ti anchor middle, and a brass center wheel. All raw out of the CNC milling machine.

The 4 micron thick Titanium spring he makes!

The resultant new watch with materials and the majority of parts other than the case, being made in Dan’s workshop, then checked for precision, finished and all assembled by one man, is quite extraordinary. The use of his Libre Excentrique titanium chronometer style detent single impulse escapement, is truly rare and is more efficient mechanically than the almost standard Swiss Lever escapement. Dan and his view of horology is well worth looking at in my opinion. Ever since I began working with Independent watchmakers 22 years ago, I don’t think I have come across this blend of ingenious and traditional watchmaking, while using newer technology and materials. A true one man band, so to speak!

Dan Spitz, a rare find in the Independent watchmaking field. He is totally dedicated to creating his own watch his way. It will be spectacular!

Dan showing me the latest version of the caliber in the CAD program.

Me paying attention like I was back in school. This was far more interesting than much of what I studied way back when!

A render of the watch.

A render of the back with a full balance bridge, rather than a balance cock that will grace the production caliber.

It’s an honor and a privilege to work with and be associated with this Independent Watchmaker, Dan Spitz. Thank you Dan for sharing your time and workshop with me. I look forward to our next visit!